Presently we feature 5 ISO certified companies specializing in swiss screw machine, micro-machined work. Typically, our customers are in industries such as:

- Aerospace (AS 9100 certification available)

- Defense (CAGE codes, ITAR and DFARS compliance)

- Medical devices (ISO 13485, FDA registration available)

- Nuclear

- Electronics

- Photonics

Experience exists for the complex, difficult in include these (failure not an option) items:

- Cannulated bone screws

- Fixation devices

- Laser/photonic devices

- Gimble, missile and drone navigation devices

- Weapons firing parts

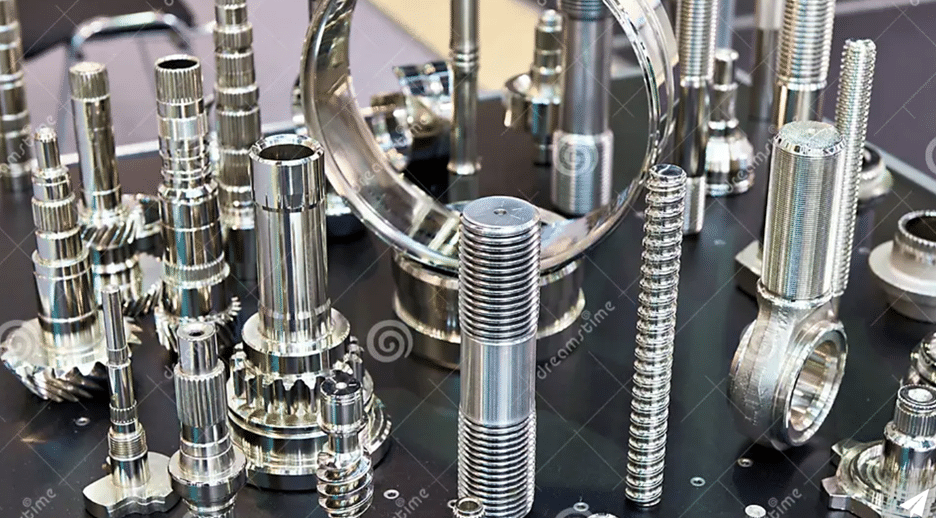

These suppliers of micro machined components are equipped to tackle even the most intricate projects. Swiss turning diameters range from 0.004” to 1.625” capable of achieving +/- 0.0001” in dimensional tolerances.

Our swiss turning shops are scattered around the eastern US, and each features a host of other capabilities. Therefore, we can offer not only state of the art micro/swiss turning precision, but choices for location (proximity is always useful) and secondary operations such as:

- Springs and wire forms, stampings, sheet metal fabrication and powder coating

- Machining and turning for larger items Milling and Turning

- Hydromats for high volume production, as well as conventional screw machining

- Honing

- OD and surface grinding

With precision and accuracy at a premium for swiss turning work, quality control and inspection excellence are crucial. Featured advanced inspection equipment includes the Global Advantage 5x5x5 mm CMM and the Oasis® non-contact video profile measurement and inspection system, which allows inspectors to measure multiple dimensions on a part simultaneously and instantly.

One of our standout offerings is a collaborative program with an in-house engineering department that works closely with clients to develop a comprehensive validation strategy and risk analysis, ensuring the most reliable and repeatable test methods are employed, facilitated by qualified machinery and trained personnel.

Our commitment shines when it comes to prototype projects, new product engineering, and R&D efforts that demand special attention, quick setups, and swift turnarounds. If your project involves components where detail matters, rest assured that we have a selection of experienced CNC swiss turning suppliers ready to meet your needs.

Our network of swiss screw machine shops has extensive experience in a wide variety of materials, key examples beyond the normal stainless steel and aluminum would include:

- Titanium

- Inconel

- Hastelloy

- Nitinol

- Brass

- Beryllium copper

- Bronzes

- ABS

- Delrin

- Aal

- Rexolite

- Ultem

- Nylon

- Noryl

- Vespel

(Just to name the most commonly required)

When you have requirements for precision, small parts and a professional experienced supplier, our network of swiss screw machine companies stands ready. Contact us today at (513) 489-5252 to discuss how our micro-machining services can help you achieve your goals