10 companies in our supplier candidate network are experts in sheet metal fabrication. Some of these also do plate fabrication, which is featured in our Large Metal Fabrications and Weldments article.

Both sheet metal and plate involve transforming flat sheets of metal into different shapes and structures, such as panels, enclosures, and machine components. The process includes cutting, bending, and assembling the metal to create the desired product.

Similarly, metal spinning might be what would work for you.

A small sample of applications include:

- seamless pipes

- turbine rings

- military products

- automotive structural parts

- agricultural tools

- hardware products

- perforated panels

- decorative designs

- POP displays

- Shelving and cabinets

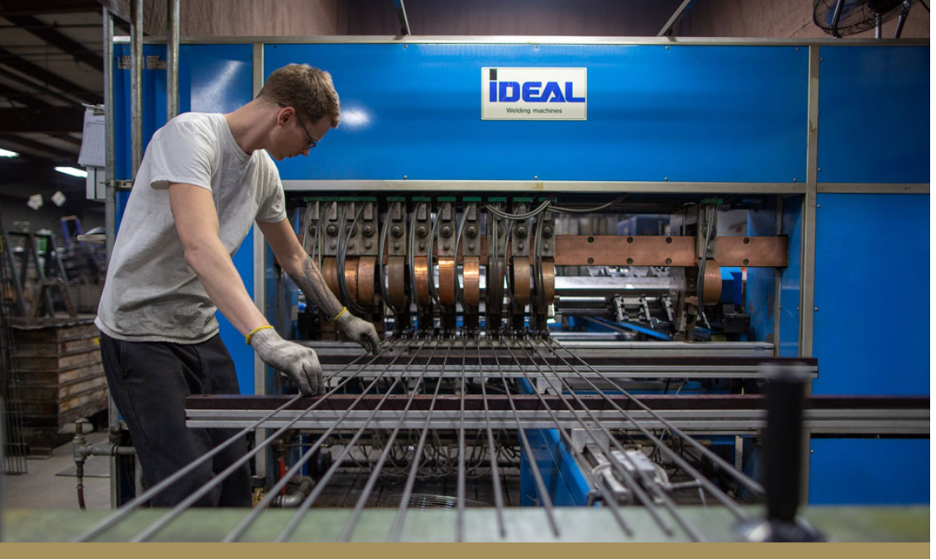

Among the many capabilities these shops have would include

- Tube bending; tube lasers

- Laser cutting (up to 6000 watts)

- Hi-definition Plasma cutting

- Water jet cutting (up to 5 axis)

- Wire mesh

- Punch press

- Painting: powder coating and liquid

Our companies have virtually every sheet metal fabrication capability available and service every industry imaginable. Many secondary capabilities are available in most shops. For example:

- Machining (some share space with complete machine shops)

- Grinding

- Wire forms and springs

- Tumbling and deburring

- Painting, shot peening and blasting

- Stamping

- Silk screen printing

- Assembly and packaging

All this means a high likelihood of being able to handle your needs under one roof. We can also usually offer multiple sources for your consideration.

If your requirements involve sheet metal, we most likely will have answers. Just give us a text or call: 513-489-5252.