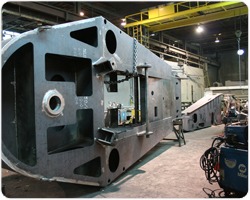

Some time ago we were involved in projects requiring plate forming and rolling. Our network now includes 3 companies with excellent capabilities for heavy fabrications, large parts and assemblies.

Some time ago we were involved in projects requiring plate forming and rolling. Our network now includes 3 companies with excellent capabilities for heavy fabrications, large parts and assemblies.

Hydraulic and mechanical presses allow fabrication of parts up to 30’ long and 4” thick without splice welding or assembly. Plate to ¾” thick can be rolled up to 13 ‘ in length. This can be with multi-radius bends or flats between bends. Shapes are made with laser cutting to 6000 watts, 94ksi water jet, and/or high definition plasma cutting with beveling. The plasma cutting equipment can handle sheets for the very large projects, with maximum cutting dimensions of 12’ x 67’.

Welding processes include MIG, TIG, automated submerged arc, CNC, robotic and more. Seam welding diameters of 2-24” can be achieved, and lifting capacity is 25 tons.

Welding processes include MIG, TIG, automated submerged arc, CNC, robotic and more. Seam welding diameters of 2-24” can be achieved, and lifting capacity is 25 tons.

If your project requires machining there are in-house capabilities for handling large parts. A new 5-axis boring mill has been recently added, and a “live tool” CNC vertical turret lathe serves as a machining center for milling and tapping using up to 15 live tools in addition to being a standard vertical lathe. This machine has a maximum part diameter of 60” and maximum height of 70”.

These shops routinely handle heavy plate fabrications for tanks and equipment for railroad, military, and transportation projects, among others. We stand ready for your projects.

These shops routinely handle heavy plate fabrications for tanks and equipment for railroad, military, and transportation projects, among others. We stand ready for your projects.

If you require even larger milling, be sure to read our next newsletter! There we will highlight a company that does high precision work for even larger projects.

If you have questions or want to find a supplier for heavy fabrications, contact me directly!