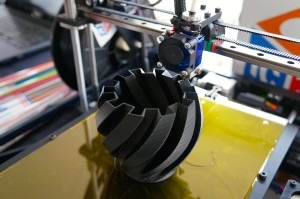

There are several methods of 3d printing but fused deposition modeling, or FDM, is the most common. Using a thermoforming technique, FDM can quickly and affordably fabricate prototyped products and their parts. As a non-laser-based process, it’s frequently used by engineers and designers to create and perfect their ideas before mass production. We feature a superior source for this exciting technology.

There are several methods of 3d printing but fused deposition modeling, or FDM, is the most common. Using a thermoforming technique, FDM can quickly and affordably fabricate prototyped products and their parts. As a non-laser-based process, it’s frequently used by engineers and designers to create and perfect their ideas before mass production. We feature a superior source for this exciting technology.

Are you ready to get your prototyped products fabricated? Call 513-489-5252 today!

Why Choose FDM for 3D Printing?

-

Speed

Parts produced with FDM can be ready in a few minutes or couple of hours, making it one of the fastest choices in 3D printing. For example, CAD drawings can be transformed into finished products in only one step.

-

Accuracy

FDM printers use a thermoplastic filament that is heated to a melting point and then extracted in layers to create a three-dimensional object. The process is accurate to within .005 inches, according to the School of Computer Science at Carnegie Mellon University.

-

Affordability

The FDM process uses thermoplastic and ceramic filament that is affordable compared to the alternatives. The modest size of the printers also means parts don’t have to be manufactured in a large facility, helping to lower the expense of producing small components.

-

Ease of Use

FDM printers can create any item designed in a CAD program. Production is set up on a computer in an easy-to-use application and is entirely controlled by the machine.

-

Scaling

This version of 3D printing automatically scales parts down to size to fit inside a production space without losing accuracy. Users can create miniature prototypes to use in presentations or as scaled-down examples in sales.